Encoder 1387 (ERN 1387): Upgrade Your Elevator Systems with Heidenhain's High-Accuracy Encoder

Encoder 1387 (ERN 1387) - also known as accelerator or engine speed tester, is a critical component in modern elevator systems. With its high accuracy and reliability, it enables precise positioning of the elevator cabin and contributes to the safety and comfort of passengers. Encoder 1387 (ERN 1387) is highly recommended by many engine manufacturers due to its ability to accurately, quietly, and remain highly durable in severe working circumstances such as: dusty and high temperature operation environments.

1. Encoder 1387 (ERN 1387): An Introduction

1.1 What is an encoder?

An encoder is a device that generates electrical signals in response to mechanical motion, such as rotational movement. In elevator systems, encoders are used to determine the position and speed of the elevator cabin, which is essential for accurate control of the elevator.

1.2 What is encoder 1387?

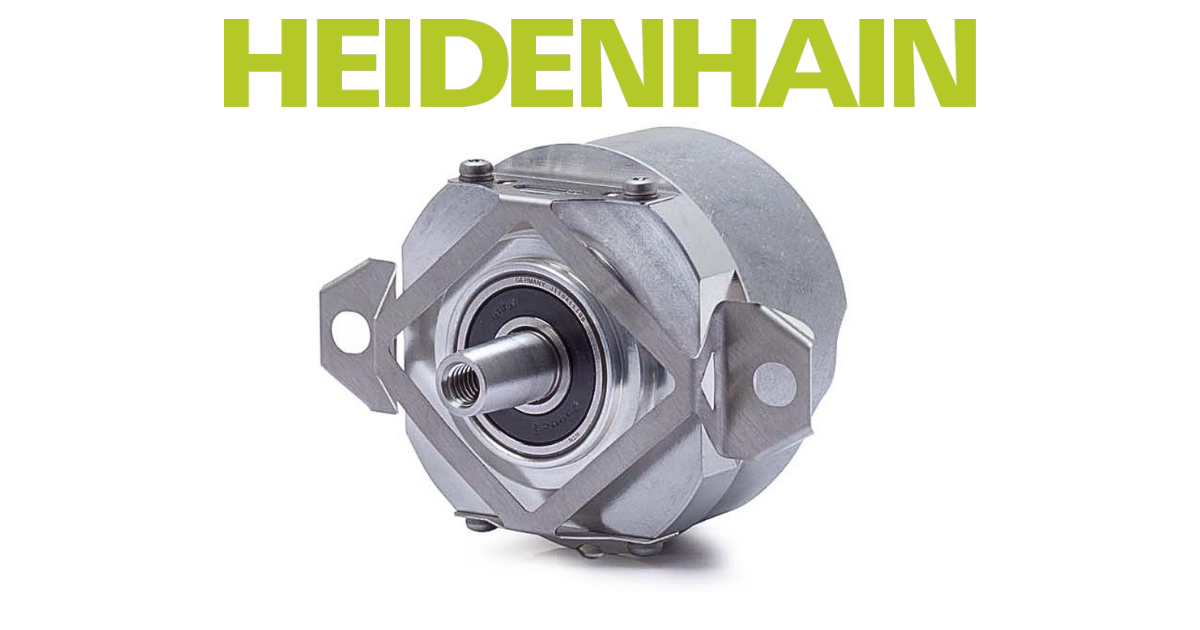

The encoder 1387 (ERN 1387) is a high-resolution incremental encoder that is widely used in elevator applications. It has a resolution of up to 10,000 pulses per revolution (PPR) and is capable of generating signals for speed, direction, and position. Its compact size and easy installation make it an ideal choice for elevator systems.

1.3 Why is encoder 1387 suitable for elevator applications?

Encoder 1387 is also known for its robustness and reliability. It is designed to withstand harsh operating conditions, such as temperature variations, vibration, and shock, without affecting its accuracy. This makes it highly suitable for elevator applications, where safety and dependability are critical.

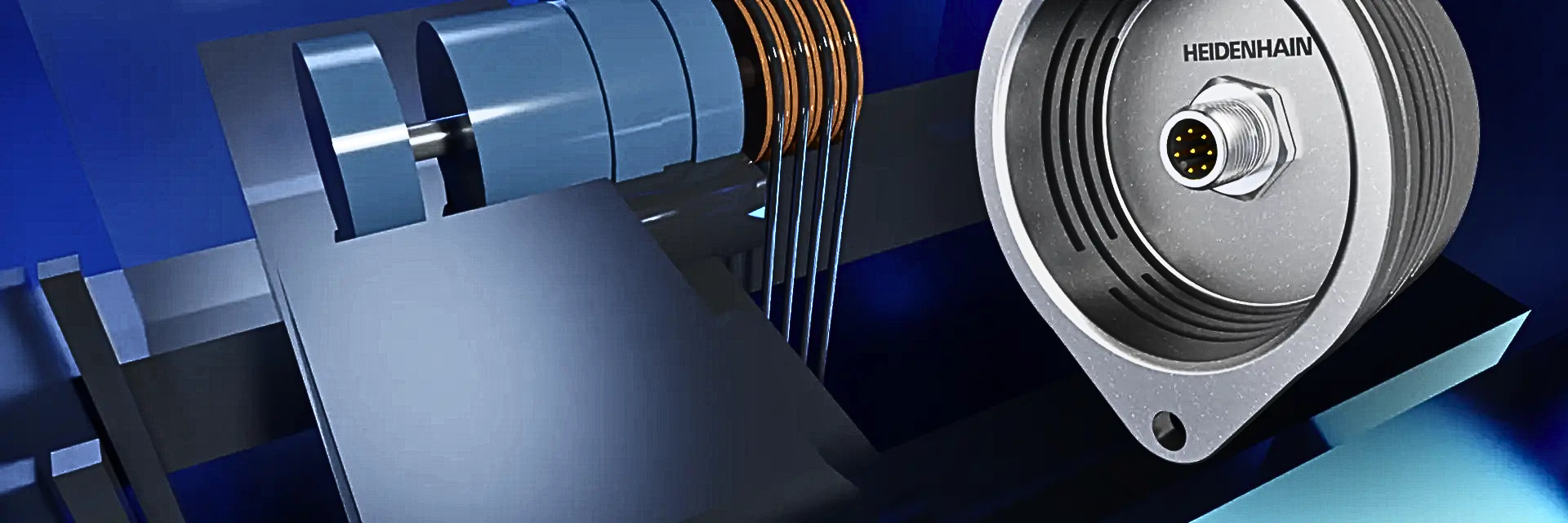

2. Heidenhain: The Leading Manufacturer of Encoder Technology

2.1 Reasons to choose Heidenhain encoders

Heidenhain is a global leader in encoder technology, and its encoders are known for their precision, reliability, and versatility. Its encoders are used in a wide range of industries, including medicine, aerospace, automotive, and industrial automation.

Heidenhain's encoders are designed to meet the most stringent requirements of modern industrial applications. They are capable of generating high-resolution signals, which are essential for accurate control of machine tools, robots, and other automated systems.

2.2 Heidenhain encoder 1387 for elevator applications

In elevator applications, Heidenhain's encoders are widely used for their high accuracy and reliability. The encoder 1387 is one such encoder that has found widespread use in elevator systems. It is a testament to Heidenhain's commitment to delivering high-quality encoder technology and has helped elevate the safety and efficiency of modern elevator systems.

3. Features of Encoder 1387

Encoder 1387 is designed to meet the specific requirements of elevator applications. Some of its features include:

3.1 High resolution

Encoder 1387 has a resolution of up to 10,000 PPR, which enables accurate position and speed control of the elevator cabin. This makes it ideal for applications that require precise positioning and high-speed data processing.

3.2 Compact size

Encoder 1387 is designed to be compact and easy to install. Its small size makes it easy to integrate into existing elevator systems without the need for major modifications.

3.3 Robustness

Encoder 1387 is designed to withstand harsh operating conditions, such as temperature changes, vibration, and shock. This ensures that it maintains its accuracy and reliability even in the most challenging environments.

3.4 Easy integration

Encoder 1387 is designed to be easy to integrate into existing elevator systems. Its compatibility with different types of communication protocols and interfaces ensures that it can be seamlessly integrated into different systems.

4. Integration of Heidenhain Encoder 1387 in Elevator Systems

4.1 Working mechanism of encoder 1387 in elevator systems application

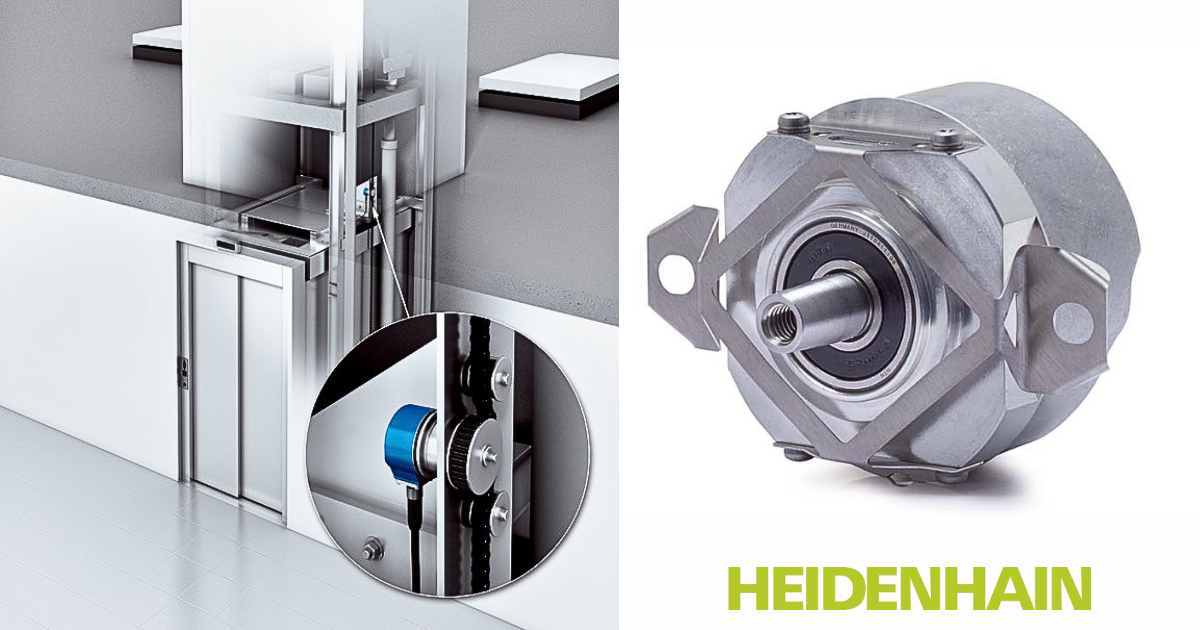

Encoder 1387 is a vital component in modern elevator systems and is used in conjunction with other components, such as motor controllers and position sensors. The encoder signals are transmitted to the control systems, which use the information to precisely control the speed and position of the elevator cabin.

The encoder provides real-time feedback on the position and speed of the elevator cabin, ensuring that it is always in the correct position and moving at the desired speed. This improves the safety and comfort of passengers, particularly during acceleration and deceleration

4.2 Heidenhain's Contribution to Encoder Technology for Elevator Systems

The reliability and accuracy of encoder 1387 are important factors in ensuring the safety of elevator passengers. Any malfunctions or inaccuracies in the encoder's signals could lead to hazardous situations. Therefore, choosing the right encoder for an elevator system is of utmost importance. The encoder must be able to operate in harsh conditions, such as temperature variations, vibration, and shock, without affecting its accuracy.

This is where Heidenhain's expertise in encoder technology comes into play. With years of experience in developing encoder solutions for various industries, Heidenhain understands the importance of accuracy, reliability, and compatibility. Heidenhain encoders are designed to work seamlessly with different types of control systems and are often customizable to meet specific requirements.

Moreover, Heidenhain's encoders are known for their high resolution, which makes them particularly suitable for high-speed applications. Heidenhain encoders can generate signals with resolutions of up to 27 bits, which enables them to provide precise feedback on the position and speed of the elevator cabin.

4.3 Heidenhain’s commitment to quality and innovation

Heidenhain invests heavily in research and development to ensure that their encoders remain at the forefront of technological advancements. This has resulted in the development of Heidenhain encoders with features such as networking capabilities, field-programmable gate array (FPGA) technology, and high-speed data processing.

5. Conclusion

Encoder 1387 is a fundamental part in modern elevator systems, making it possible for precise positioning and speed control of the elevator cabin. Its superior accuracy and durability have made an impact on elevator passengers' safety and comfort. Heidenhain has been a pioneer in the development of encoder technology for elevator systems, and whose encoders have been recognized for their precision, durability, and versatility.

If you are looking for high-quality encoder solutions for your elevator systems, consider Heidenhain's encoders. With their high accuracy and reliability, they will help improve the safety and efficiency of your elevator systems.

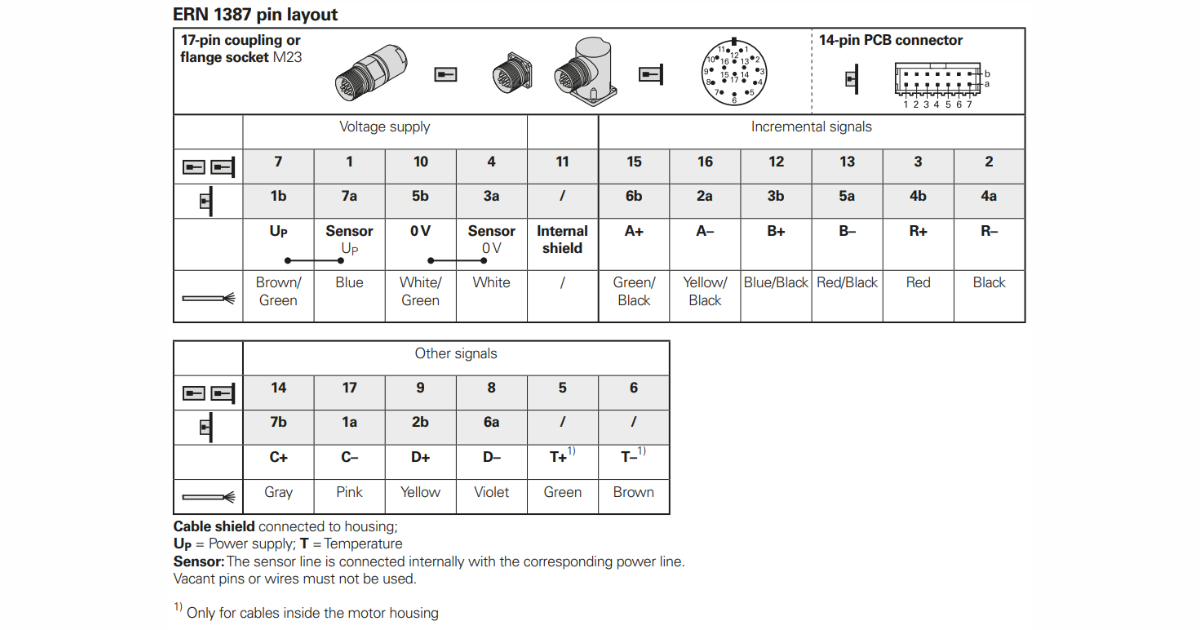

Type: ERN 1387 2048 62S14-70

Brand: HEIDENHAIN

Number of pulses: 2048

Operating voltage: DC 5V ±0.25 V

Ring count / system accuracy: 2048/±20″

Working temperature: -40 °C to +120 °C

Degree of protection against dust and water: IP40 when operating

PCB output electrical signal connection port: 14 - pins

Signal wire length: 6 m

Current consumption in operation: 130 mA under load

Cut-off frequency: 210 kHz

Dimensions: ø58* height 50 mm

Fixing screw: Hexagon M5 x 50 mm

Weight: 0.25 kg

With more than 20 years of experience in mechanical engineering, AMS Company Limited is proud to be the official exclusive distributor of HEIDENHAIN in Vietnam. We distribute all HEIDENHAIN products and provide after-sales service directly from the experts affiliated with HEIDENHAIN.

Connect us now for the best prices on the market.

AMS Company, Ltd.243/9/10D To Hien Thanh, Ward 13, District 10

Hot line: 028.3868 3738/3903 - Fax: 028.3868 3797

Read more articles